worm gear modulus 0.5 60 teeth 3d drawing

With a worm gear, loftier loads tin be transmitted at a high transmission ratio.

- i Operating principle

- 2 Manual ratio

- iii Ability transmission

- 4 Worm types

- 4.one Cylindrical worms

- 4.2 Globoid worms (enveloping worms)

- 5 Self-locking

- 5.1 Types of cocky-locking

- 5.2 Self-locking and efficiency

- 5.three Over travel

Operating principle

A special blueprint of the gear bicycle is the then-called worm. In this case, the tooth winds around the worm shaft like the thread of a screw. The mating gear to the worm is the worm gear. Such a gearbox, consisting of worm and worm bicycle, is generally referred to as a worm drive.

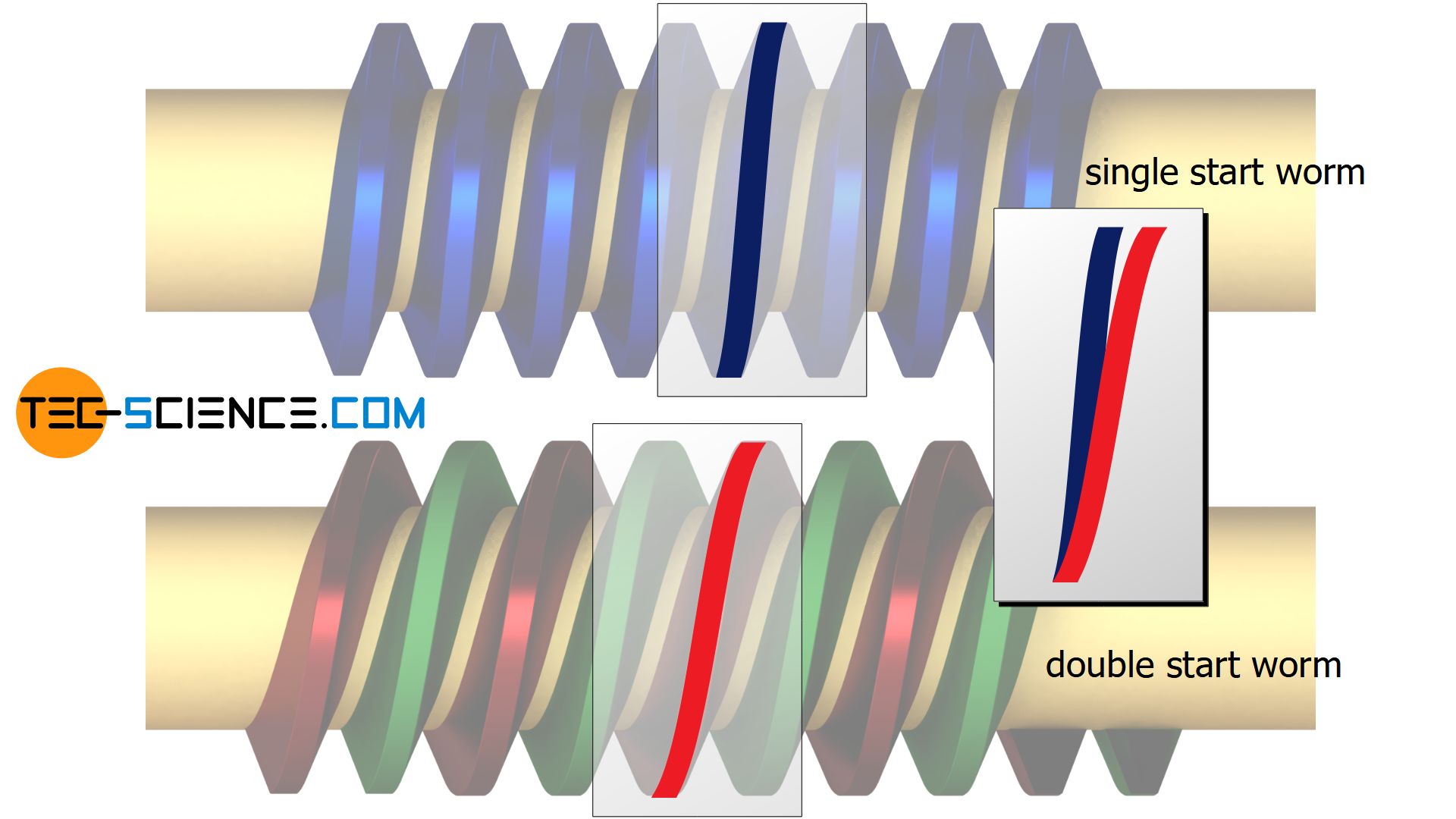

The worm can be regarded as a special case of a helical gear. Imagine at that place was merely one tooth on a helical gear. At present increment the helix bending (lead angle) and so much that the molar winds around the gear several times. The outcome would then be a "single-toothed" worm.

One could at present imagine that instead of one molar, two or more teeth would be wound effectually the cylindrical gear at the same time. This would then correspond to a "double-toothed" worm (2 thread worm) or a "multi-toothed" worm (multi thread worm).

The "number of teeth" of a worm is referred to equally the number of starts. Correspondingly, one speaks of asingle start worm, double start worm or multi-start worm. In general, mainly single start worms are produced, but in special cases the number of starts tin also exist upwardly to iv.

Worms are basically spirally wound "teeth" that spiral into the worm gear and bulldoze information technology!

Transmission ratio

Since the number of starts is of a worm ultimately the equivalent to the number of teeth of a toothed wheels, the number of teeth to be used to determine the transmission ratio \(i\) corresponds to the number of starts of the worm:

\begin{align}

\label{uebersetzungsverhaeltnis}

&\boxed{ i = \frac{z_{\text{worm gear}}} {z_{\text{worm}}} } ~~~ \text{} z_{\text{worm}} = one … iv ~~~\text{depending on the number of starts}\\[5px]

\cease{align}

That the number of starts of a worm corresponds to the number of teeth of a cog bike can also be seen clearly from the blitheness below of a single showtime worm drive. With one rotation of the worm the worm thread pushes straight on past one position. The worm gear is thus moved on by one tooth. Compared to a toothed wheel, in this case the worm really behaves as if it had only ane tooth effectually its circumference.

On the other hand, with i revolution of a two start worm, two worm threads would each motility ane tooth further. In total, ii teeth of the worm wheel would have moved on. The 2 start worm would so carry similar a two-toothed gear.

The animation below shows the comparison between a double start worm and the single offset worm. Note that the worm gear driven by the double get-go worm rotates twice as fast equally the worm gear of the single first worm (lower transmission ratio).

Due to the more often than not very low number of starts of the worm (usually one!) and the insufficiently large number of teeth of the worm gear, the transmission ratio of worm drives is correspondingly very loftier. With worm drives, very high transmission ratios of more than 100 can be achieved in a space-saving mode!

Since several sections of the worm thread are more often than not engaged simultaneously while meshing with the worm gear, the load chapters of such worm drives is very loftier, i.e. very high ability can be transmitted. In add-on, worm drives are very quiet due to the continuous sliding of the flanks between worm and worm gear and the required lubrication or cooling (more than on this in the following section).

Worm drives are very infinite-saving and are suitable for transmitting high power at loftier transmission ratios!

Power transmission

In worm drives, power is transmitted almost exclusively through sliding between the flanks of the worm and the worm gear, i.due east. the flanks slide onto each another equally a screw. Worms are ultimately a special example of screw gears. In dissimilarity to screw gears, which generate a indicate-shaped flank contact, worms have a linear flank contact. This results in the advantage of transmitting higher power at higher transmission ratios.

Due to the sliding processes and the associated friction on the flanks, the efficiency of worm drives is generally lower than wirh spur gear drives or bevel gear drives. Due to the heat generated past friction, worm drives must exist cooled at high ability transmissions in addition to lubrication.

Worm types

Depending on the shape of the worm, worm drives tin can be classified differently.

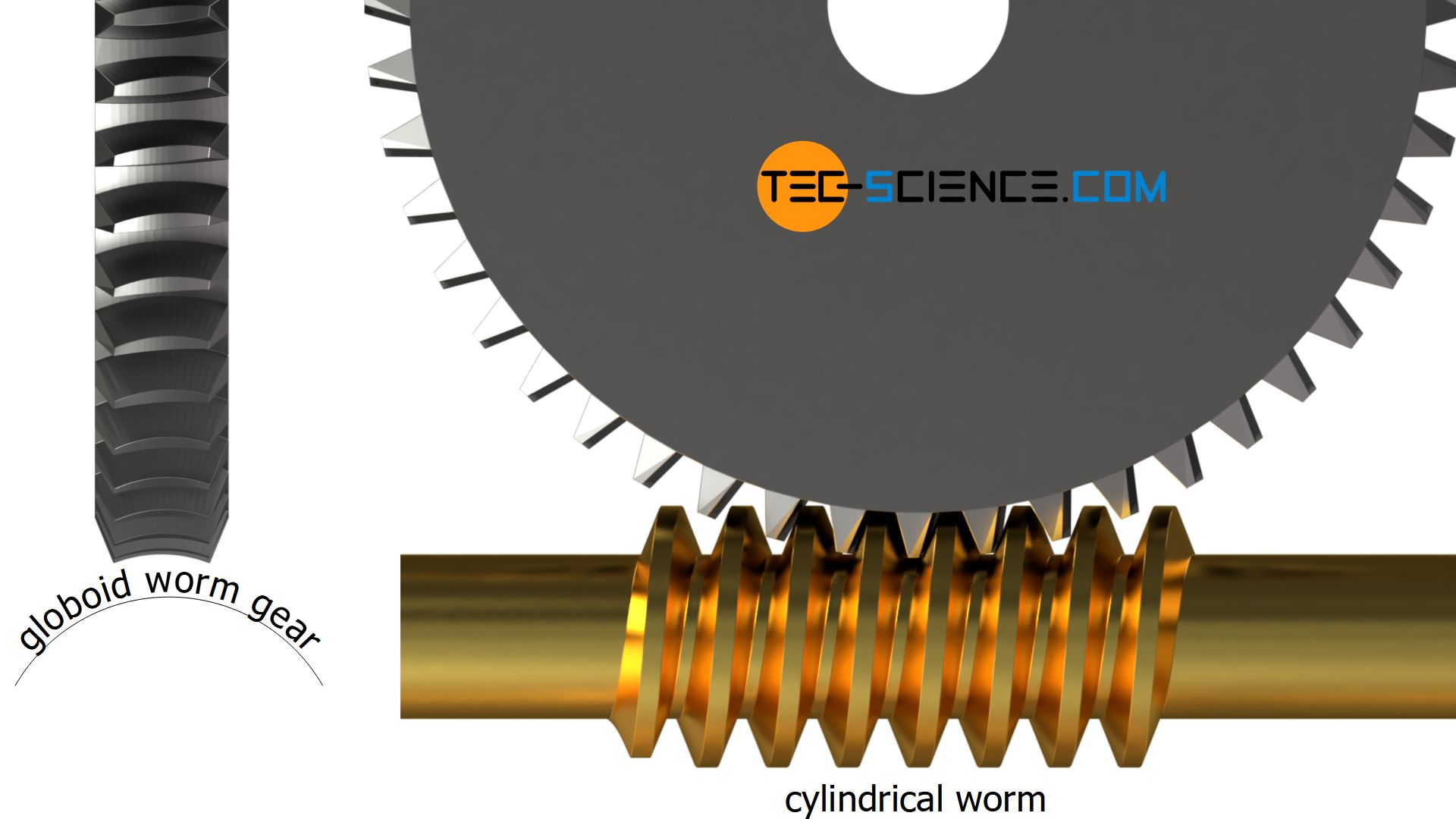

Cylindrical worms

If the external shape of the worm has a cylindrical design, the worm is called a cylindrical worm. If the worm gear maps this cylindrical contour in the cross-section of the circumference, the gear bike is called globoid worm gear. Due to the relatively simple production of a cylindrical worm, this variant is preferably used (cylindrical worm drive).

Cylindrical worms are relatively easy to produce and are preferred for toll reasons!

Globoid worms (enveloping worms)

In a modified variant, the external shape of the worm describes an arc which partly envelopes the globoid worm gear. 1 then speaks of a globoid worm or an enveloping worm (globoid worm drive).

Compared to a cylindrical worm, with a globoid worm it is achieved by wrapping the worm wheel that more sections of the worm thread are involved in meshing. Globoid worms can thus transfer higher powers than cylindrical worms.

The product of a globoid worm is relatively complicated compared to a cylindrical worm and therefore expensive. Such globoid worms are therefore less used.

With globoid worms (enveloping worms) higher powers can be transmitted; however, they are relatively expensive due to the complex production!

In special cases, the globoid worm can fifty-fifty exist paired with a unproblematic helical gear. However, this requires a special adaptation of the worm to the helical gear, which makes production correspondingly expensive. Still, the advantage is the lower blueprint effort, since the radial positioning of the worm when mating with a simple helical gear allows a greater tolerance than is the case with a globoid worm gear.

Cocky-locking

Transmissions are called cocky-locking if torque transmission tin can only take place in one direction. The gear unit of measurement tin merely be set in motion by the input shaft. Notwithstanding, the gear unit cannot be prepare in motion past the output shaft. Input and output are thus fixed.

Worm drives are often self-locking due to their special operating principle. This self-locking is due to the screw motion of the worm thread at low lead angles. Thus the worm tin bulldoze the worm wheel by its helical flank motion, only vice versa no motion can usually be produced. The contact force of the worm gear flanks confronting the thread flanks of the worm is so big and the atomic number 82 angle but to small that the resulting frictional force prevents a rotational motion. For this reason, self-locking worm drives are e'er driven by the worm.

Cocky-locking worm drives can merely exist set up in movement by the worm!

Note that the thread of a unmarried start worm generally has a smaller lead bending than multi-start worms. Single starting time worms twist more than and are therefore more than often cocky-locking than multi start thread worms. Conversely, this ways that self-locking can be prevented (if desired) with multi-thread worms.

Types of self-locking

Self-locking worm drives are used, for case, in lifting platforms. The self locking machinery prevents the platform from moving down again on its own when the motor is switched off (statically self-locking). An additional holding brake tin exist dispensed with if the self-locking machinery is large enough and cannot be released by whatever vibrations. If such a release should be the instance, so oftentimes a "rattling" of the worm drive is to be noted.

Depending on the application, it must also be ensured that the gear unit stops automatically on its own if the motor is switched off when lowering the lifting platform (dynamically self-locking or self-braking).

Every bit this example shows, a stardom must therefore exist fabricated betwixt ii types of cocky-locking:

- self-locking(statically self-locking)

"self-locking from the resting state" (static friction is not overcome) - cocky-braking (dynamically self-locking)

"self-braking rom the operating state" (sliding friction acts every bit a brake)

A gearbox is considered statically self-locking if information technology has come to a halt and cannot be set in motion past the worm cycle under a vibration-gratis state!

However, vibrations or shocks can eliminate this static self-locking machinery and cause the gear unit to start upward nether output-side load.

A gearbox is considered self-braking (dynamically cocky-locking) if the disengaged gear comes to a halt after a brusk fourth dimension when a load on the output is present (e.m. lowering a lifting platform).

Self-locking and efficiency

Self-locking is ever associated with friction, without which there would otherwise be no self-locking. Cocky-locking gears therefore ever have a lower efficiency than comparable non-cocky-locking gears. Usually the efficiency of self-locking worm drives is less than 50 %. Above 50 %, worm drives are often non-cocky-locking.

If self-locking is not required, the focus is commonly on the highest possible efficiency. Efficiencies of well over 90 % are also possible for worm drives, but without self-locking in principle. However, if for economic reasons a loftier efficiency is required with "cocky-locking", then the gearbox must be equipped with a holding brake.

As already explained, the private threads of a multi-commencement worm have a larger pitch angle and thus a lower tendency to self-locking, since the friction forces are lower due to the reduced "wedge effect". This increases the efficiency!

Multi-start worms take higher efficiencies and a lower tendency to self-locking!

Over travel

Cocky-locking tin become problematic when big masses are moved with the worm wheel. If the worm drive is and then suddenly switched off, the worm wheel is nevertheless trying to move due to the inertia of the driven mass. Nonetheless, since the worm does not let a rotational move due to self-locking, enormous flank loads tin can occur and fracture the worm.

In such cases, the worm cannot be stopped abruptly, only must rotate a fiddling scrap further after switching off the gear drive (called over travel). Special lubricants can assistance the worm to over travel. It may also be necessary to implement special over traveling devices that bring the manual slowly to a standstill.

If large masses are moved with worm drives, information technology must be ensured that the gear does not come to a standstill immediately after switching off!

Source: https://www.tec-science.com/mechanical-power-transmission/gear-types/worms-and-worm-gears/

Post a Comment for "worm gear modulus 0.5 60 teeth 3d drawing"